How Deal Tombstones Are Made ?

September 4, 2023, In Tips & Tricks

Deal tombstones are commemorative mementos that mark the closure of a significant business deal or transaction. These mementos vary in material, design, and manufacturing process, with each offering distinct characteristics and challenges. Let’s take a look at how each type of material can be processed and how they differ in terms of design flexibility, colours, and essence.

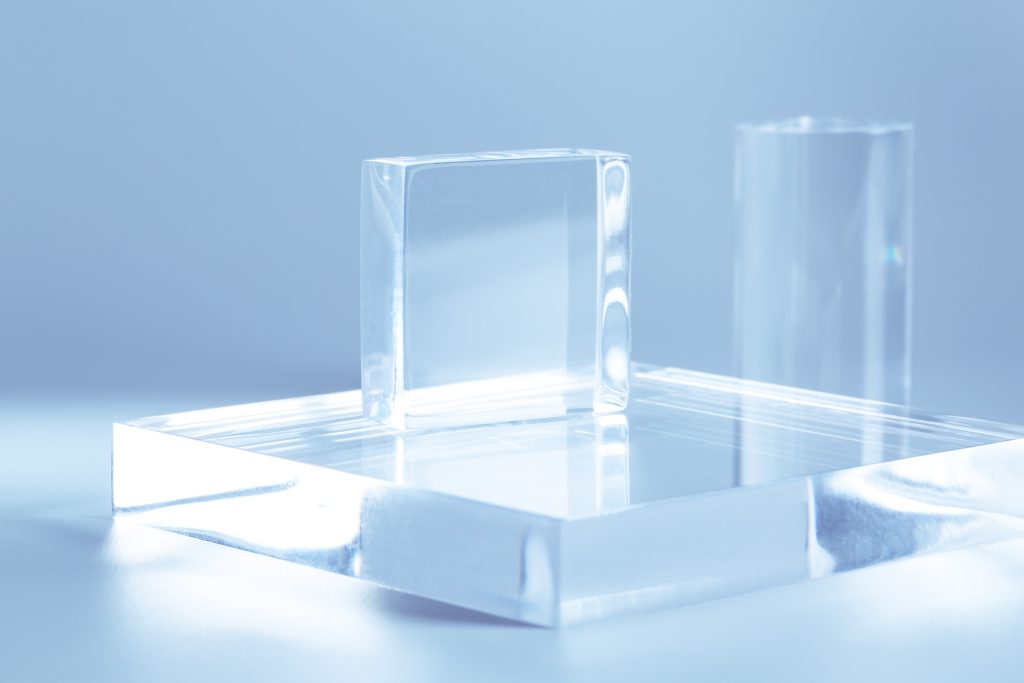

How Lucite (Acrylic) Tombstones Are Made?

The Design Flexibility of Lucite

Lucite is renowned for its wide array of design possibilities. Not only can it be cut or molded into virtually any shape—from simple geometric forms like rectangles and circles to more complex shapes like stars or custom logos—but it can also encapsulate objects such as coins, documents, or small mementos.

This feature makes it incredibly popular for projects that require a layering of visual elements or a three-dimensional display. Designers often use this quality to create multi-layered pieces that can include text, graphics, and real-world objects in one cohesive display.

Acrylic’s Variety of Colors and Essence:

Lucite can be produced in a transparent form or tinted to various colours, offering flexibility in aesthetic presentation. Its colour range can be from transparent and crystal-clear to solid, opaque colours like black or white and everything in between, including neon shades.

This providesmuchf room for customization based on brand colours or the theme of the deal or event being commemorated. The essence of Lucite deal tombstones tends to be contemporary and modern, suitable for settings ranging from corporate offices to trendy start-ups.

Lucite Molds and Forming Techniques:

The manufacturing process of Lucite generally involves the creation of a mold, which can be made from a variety of materials, including rubber or more rigid composites.

Liquid Lucite is then poured into this mold and subjected to a curing process, which often involves heat and pressure to facilitate polymerization. This makes the liquid solidify into the shape of the mold, capturing any embedded objects or prints in the process.

How to Take Care of Your Lucite Deal Toy?

Though durable, Lucite is susceptible to scratches and should thus be handled with care. Cleaning it is relatively straightforward; a soft cloth with mild soap and water usually suffices.

It’s advisable to avoid abrasive cleaners or scrubbers, as they can leave scratches. A microfiber cloth is often recommended for polishing and removing fingerprints.

How Crystal Deal Tombstones Are Made?

Crystal Deal Toys Design Flexibility:

Crystal is somewhat less versatile than Lucite when it comes to shaping, primarily because it starts as a solid material that has to be cut or molded. However, what it lacks in shape flexibility, it makes up for in elegance and a sense of luxury.

Designs are usually created through precise engravings or etchings, which can capture high levels of detail. Text and logos often appear as frosted elements against the clear backdrop of the crystal, and complex 3D designs can be laser-etched within the crystal block for a stunning visual effect.

Crystal Financial Tombstone Timeless Essence:

Crystal deal tombstones are generally transparent, and their appeal lies in their clarity and the way they refract light. They often feature beveled edges that create beautiful light patterns.

The essence of crystal is one of timeless elegance and high value, making these tombstones suitable for commemorating particularly significant deals or milestones.

Molds and Forming Techniques of Crystal Deal Tombstones:

Crystal manufacturing for deal tombstones often involves a form of glassblowing for round or organic shapes or pressing for more geometric shapes.

Highly skilled artisans may hand-cut the crystal for intricate patterns and designs. Machine-cutting techniques can also be used for precision, often in combination with laser etching for detailed internal designs.

How to Take Care of Your Crystal Deal Toy?

Crystal tombstones require careful handling due to their fragility. Cleaning should be done using a soft lint-free cloth, and mild soap can be used for removing fingerprints.

It’s crucial to avoid temperature extremes as they could cause the crystal to crack. Special crystal cleaning solutions are available for restoring brilliance but are generally not necessary unless the item becomes dull or cloudy.

How Custom Wood Deal Toys Are Made?

Design Flexibility of Custom Wood Trophies:

Wooden tombstones offer a rich, organic feel that’s particularly suitable for deals or milestones with historical or traditional significance. The material is often carved, laser-engraved, or even inlaid with other materials like metal or stone for a diverse range of aesthetic options.

From intricately carved details to simple, elegant forms, wood can be manipulated in a variety of ways to produce something that feels both timeless and highly customized.

Various Wood Deal Toys Colors and Essence:

The colour options for wood are generally determined by the species of wood selected. Hardwoods like oak, cherry, or mahogany offer rich, deep colours while softwoods like pine can offer lighter shades.

Woods can be stained to alter their colour or treated with a clear varnish to highlight their natural grain. The essence of a wooden deal tombstone is one of lasting significance and traditional value.

Wood Deal Tombstones Forming Techniques:

Blocks of wood are cut, carved, and shaped using a combination of manual and machine tools.

CNC (Computer Numerical Control) machines are often used for precise cuts and intricate patterns, while laser engraving can provide surface-level details like text or logos.

How to Take Care of Your Custom Wood Deal Toy?

Wooden tombstones should be kept away from direct sunlight, which can fade the colour and dry out the wood, leading to cracks. A controlled climate is essential to prevent warping or splitting.

Dusting should be regular, and a specialized wood cleaner or polish can be used sparingly to maintain the lustre.

How Custom Metal Awards Are Made?

The Design Flexibility of Metal Deal Tombsontes:

Metal offers a sleek and modern aesthetic that can range from the high polish of stainless steel to the aged patina of bronze or copper. Its inherent strength allows for slim, elegant shapes and the material can be cut, etched, or molded to produce a variety of designs.

While the level of detail might not match that of carved wood or etched crystal, metal can still be manipulated into intricate forms using techniques like laser cutting or CNC machining.

Metal Various Textures, Colors and Finishes:

The colour of a metal tombstone will be determined by the type of metal used. Options like gold, silver, bronze, and copper each bring their distinct hues to the table.

Finishing techniques can also alter the tombstone’s appearance, from shiny, reflective surfaces to matte or brushed finishes. The essence of a metal deal tombstone is often associated with strength, permanence, and modernity.

Metal Deal Toys Molds and Forming Techniques:

Metal tombstones can be manufactured using a variety of techniques. Casting involves pouring molten metal into a mold and is ideal for more complex shapes.

For simpler, flatter designs, etching or laser cutting is often used. CNC machining can also be employed for highly intricate or precise designs.

How to Take Care of Your Custom Metal Deal Tombstone?

Metals like silver and copper may tarnish over time and require polishing to restore their original sheen. Stainless steel is relatively maintenance-free but may require occasional cleaning with a damp cloth to remove fingerprints or smudges.

It’s advisable to avoid abrasive cleaners that could scratch the surface.

How 3d Printed Custom Deal Tombstones Are Made?

Design Flexibility of 3d Printed Awards:

The level of design flexibility offered by 3D printing is unparalleled. Complex geometries, intricate lattice structures, and even moving parts can be incorporated into a single piece without the need for assembly.

The limits are generally defined only by the capabilities of the 3D printer and the properties of the printing material.

Colors and Finishes Possibilities with 3d Printed Deal toys:

3D-printed tombstones can be produced in a variety of colours, depending on the type of material used for printing. Some 3D printers even offer multi-colour capabilities. Finishes can range from glossy to matte, and post-processing can include sanding or painting to achieve the desired appearance.

The essence of a 3D-printed deal tombstone tends to be modern and innovative, often capturing the pioneering spirit of the deal it commemorates.

3d Printed Trophies Forming Techniques:

3D printing employs additive manufacturing techniques, meaning the material is built up layer by layer according to a digital model. This eliminates the need for molds, reducing the lead time and costs associated with mold production.

The most common techniques include Fused Deposition Modeling (FDM), Stereolithography (SLA), and Selective Laser Sintering (SLS), each with its pros and cons in terms of material properties and finish.

How to Take Care of Your Custom 3d Printed Deal Tombstone?

Taking care of a 3D-printed tombstone depends largely on the material used. PLA, a common 3D printing material, is biodegradable and should be kept away from high heat and moisture.

More durable materials like ABS or resin require less specific care but may benefit from occasional dusting and cleaning with a damp cloth.

Each type of material brings its own set of advantages and limitations in terms of design flexibility, colours, and manufacturing methods. Proper care for each will ensure that these mementos continue to commemorate significant milestones for years to come.